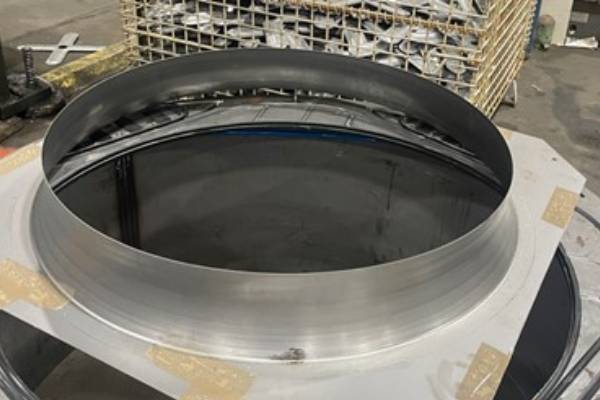

An industrial fan manufacturer engaged TMS to engineer a solution to produce deep venturi’s, curls, flanges, beads and punched holes on rolled drums ranging in sizes from 17 inches to 86 inches. The Lucas VBH is the most versatile machine in the industry, designed to form between 9 inch – 90 inch parts. The VBH performs several operations (flange/bead/curl/punch/trim) on one automated pass. The process improvements provided by TMS will help the customer increase EBITDA by lower fixed and variable costs by:

- Lead times lowered from 8 weeks to 2 weeks.

- Welding parts dropped by 40%

- 70% lower scrap + labor savings associated with less rework

- Welding personnel previously used for beading, flanging and making deep venturi’s, now performed on the Lucas VBH

Estimated payback period on Lucas VBU at the time of order was 22 months, actual payback period 9 months.